Best CNC Glass Groove Milling Machines for Precision Cutting?

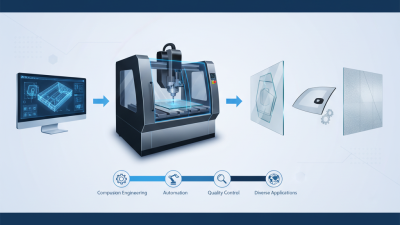

In the world of precision cutting, the CNC Glass Groove Milling Machine stands out as a game changer. Experts like John Carter, a renowned specialist in machining technology, emphasize its importance: “Precision is key in glass milling.” This technology has revolutionized how glass is shaped and processed.

CNC Glass Groove Milling Machines enable exact grooves and designs that were once nearly impossible. They can handle intricate patterns while maintaining accuracy. For manufacturers, investing in this technology can elevate product quality. However, it comes with challenges. Setup and programming can be tricky.

Moreover, not all machines deliver the same level of precision. Some may falter under certain conditions. It's essential to choose wisely. An investment in knowledge, as much as in machinery, is vital for success. The right choice can make a significant difference in production efficiency and overall results.

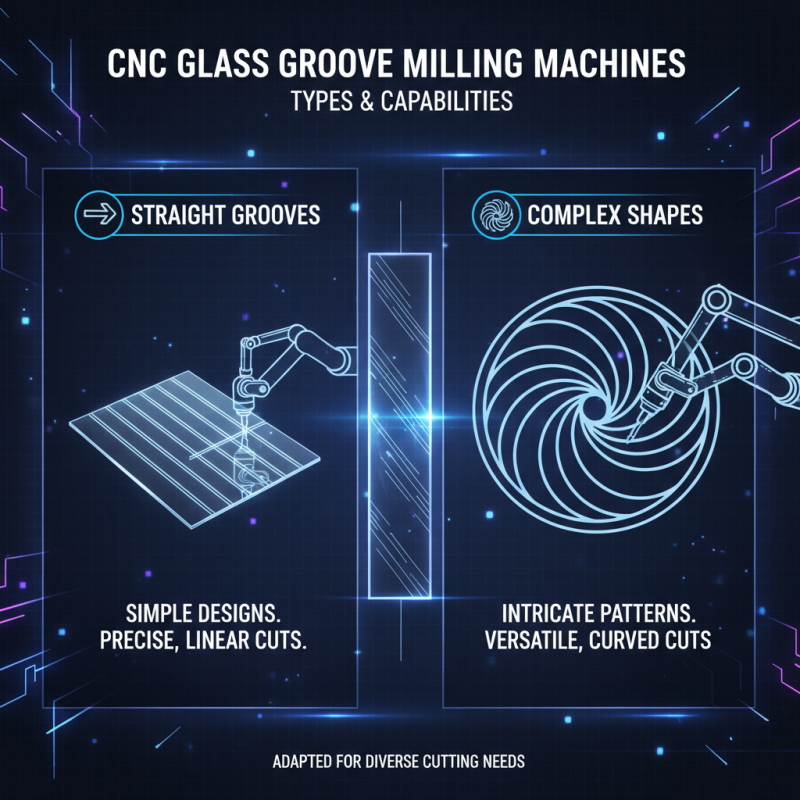

Types of CNC Glass Groove Milling Machines for Precision Cutting

When exploring CNC glass groove milling machines, it's essential to consider their types. Different machines serve various cutting needs. For instance, some machines focus on straight grooves, providing precise cuts for simple designs. Others are designed for complex shapes. These advanced machines enable intricate patterns, offering versatility to the user.

Another crucial type is the multi-axis milling machine. These machines allow movement on multiple planes. This capability enhances precision in cutting complex glass shapes. However, using multi-axis machines can complicate operations. It requires skilled operators to manage the settings and tooling effectively. In some cases, users may find the learning curve steep and may waste materials during the process.

Moreover, there are hybrid machines that combine milling and engraving features. This type provides unique opportunities for customization. However, they may not always deliver the precision expected. Operators might face challenges while switching between functions. It's essential to understand the strengths and limitations of each machine type. This knowledge helps in choosing the right tool for specific tasks.

Key Features to Consider When Selecting a CNC Glass Milling Machine

When selecting a CNC glass milling machine, precision is paramount. Look for machines that offer high accuracy. According to a recent industry report, precision milling machines can achieve tolerances of ±0.01 mm. This level of accuracy is critical for intricate designs and fine details in glass work.

During the selection process, consider the spindle speed. Higher speeds allow for smoother finishes and quicker cuts. Machines with a speed range of 10,000 to 20,000 RPM are often ideal. They can effectively manage different materials, including various types of glass. It's essential to balance speed with control, as excessive speed may lead to unwanted chipping or cracking.

Another important feature is the programming interface. An intuitive interface can reduce the learning curve for operators. A complex interface might lead to errors or inefficient workflows. Many studies suggest that user-friendly software significantly improves productivity.

Don't overlook the machine's build quality. Sturdy constructions can withstand the vibrations and stresses of milling. Inadequate support can lead to inaccuracies over time, prompting reflection on how to enhance production. Overall, focus on these key aspects for a successful CNC glass milling experience.

Top Brands and Models: Benchmark CNC Glass Groove Milling Machines

When it comes to CNC glass groove milling machines, precision is key. These machines are designed specifically for intricate cutting tasks, enhancing workflow efficiency. The CNC technology ensures that each cut is consistent, reducing waste. Industry reports suggest that the market for such machines is growing. They indicate a rise of 8% in demand for precision cutting tools, especially in architectural applications.

Choosing the right CNC machine involves understanding your specific needs. Look for machines with varying speed settings. This allows for adjustments based on the thickness of the glass used. The goal is to achieve smooth edges. A machine's software capabilities also matter. Robust software can optimize the cutting process, allowing for complex designs.

Tip:

Regular maintenance of your CNC machine is crucial. This can prolong the machine's life and maintain cutting quality. A worn tool can lead to imperfections in the finished product.

Another aspect to consider is the design of the machine itself. Compact and adaptable machines can fit into smaller workshops. Yet, they should not compromise on power. Balancing size and capability is essential. As reported, operators often regret choosing a machine that lacks versatility.

Maintenance Tips for Ensuring Precision in CNC Glass Milling

Regular maintenance is crucial for ensuring precision in CNC glass milling machines. Studies suggest that up to 30% of machine downtime results from unexpected failures. Therefore, scheduled maintenance can prevent these costly interruptions. Check key components like the spindle, bearings, and coolant systems regularly. A report from the International Journal of Precision Engineering indicates that proper lubrication can enhance machine life by 20%.

In addition to mechanical checks, software updates cannot be overlooked. Outdated software can lead to errors in milling processes. The precision of cuts and grooves can suffer if the software does not accurately interpret designs. Operators should observe their machines’ output closely. Small inconsistencies can indicate underlying issues requiring immediate attention.

Moreover, keeping the workspace clean is as important as the machines themselves. Dust can settle on precision tools and affect their performance. It may seem minor, but even a speck of dirt can lead to significant measurement deviations. Implementing a routine cleaning schedule will help maintain accuracy. Experts recommend using air compressors and soft brushes rather than cloth, which can leave lint behind. Attention to these details yields better outcomes in glass milling processes.

Applications and Industries Utilizing CNC Glass Groove Milling Machines

CNC glass groove milling machines are essential in various industries. They offer precision cutting for glass materials, ensuring intricate designs and smooth finishes. These machines are widely used in the construction, automotive, and furniture sectors. For example, in construction, they create precise glass fittings for windows and facades.

The automotive industry benefits from CNC milling in crafting glass components, such as windshields. This machine enhances both safety and aesthetics. In furniture, designers utilize these machines to make stylish glass tabletops. The result is a blend of creativity and functionality.

Despite their advantages, there are challenges. Some operators may encounter issues with calibration. Inconsistent settings can lead to uneven cuts. Thus, ongoing training is necessary. Regular maintenance is also crucial to avoid machine breakdowns. Striking a balance between quality and efficiency is an ongoing pursuit in this field.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us