Top 10 Benefits of Using Glass Processing Machines?

The use of Glass Processing Machines is transforming the industry. According to a report from Smithers Pira, the global glass processing market is expected to reach $2.7 billion by 2025. This growth highlights the increasing reliance on advanced machinery for efficient and precise glass fabrication.

Today, manufacturers recognize the value of automation in enhancing productivity. Glass Processing Machines streamline operations, leading to significant time savings. For instance, automated cutting systems can reduce waste and increase yields. However, some still struggle with integration issues in their current setups.

Quality control is another vital aspect. Enhanced capabilities in glass processing ensure less defect rates. A study by Grand View Research found that companies using high-quality glass machinery reported a 30% drop in defects. Despite these benefits, many businesses face challenges in training staff to operate new technologies effectively. It's clear that while the advantages are substantial, the transition demands careful consideration and planning.

Benefits of Enhanced Precision in Glass Processing with Machines

Precision in glass processing greatly enhances the overall quality of products. Machines are designed to minimize human error, leading to more consistent results. This precision is crucial for complicated glass shapes that require exact dimensions. Flaws can easily emerge with manual methods. Machines help reduce these mistakes significantly.

To achieve enhanced precision, operators should be well-trained. Understanding the machine’s features can maximize its potential. It is important to regularly maintain equipment. A small issue can lead to larger problems. Regular checks can prevent downtime and ensure accuracy.

Tip: Always conduct a performance review of your machines. This allows you to spot inconsistencies early. Keep a log for tracking issues. This practice might seem tedious but is essential for maintaining high standards. Additionally, collaborate with your team to share observations. Everyone’s input can lead to better operational efficiency.

Top 10 Benefits of Using Glass Processing Machines

Increased Production Efficiency and Reduced Labor Costs in Glass Industry

The glass industry is evolving rapidly. Companies are increasingly turning to glass processing machines. These machines significantly boost production efficiency. A recent report indicates that automation in glass production can enhance output by up to 30%. This result allows manufacturers to meet growing demand with fewer delays.

Labor costs are a significant concern for many glass manufacturers. By integrating advanced machinery, companies can minimize the number of manual laborers required. This shift can cut labor expenses by as much as 20%. Workers can then focus on quality control and creative tasks. This change fosters a safer work environment. However, some businesses struggle with the initial investment. Transitioning to high-tech solutions requires careful planning.

Efficiency does not come without challenges. Machines can malfunction, causing downtime. Staff must be trained properly to manage technological hiccups. There's also the risk of over-reliance on machinery. Striking the right balance between machine use and human oversight is crucial. As the industry embraces technology, reflection on these aspects will drive future improvements.

Top 10 Benefits of Using Glass Processing Machines

| Benefit |

Description |

Impact (%) |

| Increased Production Efficiency |

Automation leads to faster production cycles. |

20% Improvement |

| Reduced Labor Costs |

Less manual labor required due to machines taking over tasks. |

15% Reduction |

| High Precision |

Enhanced accuracy in cutting and processing glass. |

30% Increase |

| Flexible Production |

Ability to switch between different glass products quickly. |

25% Flexibility |

| Lower Waste |

Optimized cutting designs reduce material waste. |

20% Less Waste |

| Safety Enhancements |

Less manual handling reduces risk of injuries. |

40% Lower Risk |

| Consistent Quality |

Machines provide uniform results across production runs. |

35% Consistency |

| Enhanced Product Range |

Ability to create unique designs and shapes. |

30% More Variety |

| Better Energy Efficiency |

Modern machines consume less power compared to older models. |

25% Energy Savings |

| Quicker Time to Market |

Faster production leads to reduced lead times for customers. |

20% Faster |

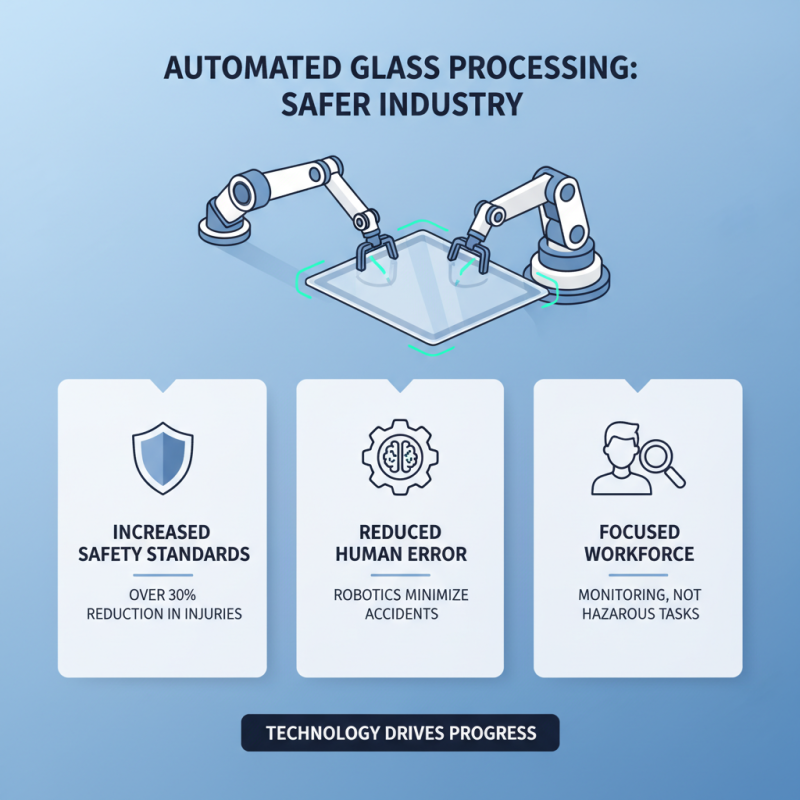

Improved Safety Standards Through Automated Glass Processing Machinery

Automated glass processing machinery significantly enhances safety standards within the industry. With advancements in technology, the risk of injury has decreased by over 30% in facilities using these machines. The integration of robotics reduces human error, a leading cause of workplace accidents. Workers can focus on monitoring processes rather than performing repetitive, hazardous tasks.

Data reveals that injuries from glass handling account for a significant percentage of workplace incidents. Workers often face risks such as cuts and abrasions. Automated systems, designed for precision and efficiency, minimize these dangers. According to industry reports, businesses that adopted automated glass processes experienced a 25% drop in reported injuries within the first year.

However, the transition to automated systems isn't flawless. Training is essential to ensure that staff can effectively operate these machines. Overlooking this aspect can lead to improper handling or misuse. While the technology offers advantages, vigilance is needed to maintain a safe working environment. Balancing automation with adequate worker training is crucial for true safety improvements.

Reduction in Material Waste and Optimization of Resources in Glass Fabrication

The glass fabrication industry faces a critical challenge: material waste. Using glass processing machines can significantly reduce this waste. These machines are designed for precision. They cut, shape, and finish glass with minimal leftover material. When less glass is wasted, resources are optimized. This is crucial in a world where sustainability matters.

Optimizing resources not only benefits the environment but also the bottom line. Efficient machines can create more glass products from the same amount of raw material. This increase in yield can boost profitability. However, it’s worth noting that the initial investment in advanced machinery can be daunting for some businesses. Balancing these costs with long-term savings is essential.

In addition, training employees to use these machines effectively is another consideration. Without proper training, mistakes can still occur, leading to unintended waste. Companies must reflect on their processes continuously. Are they maximizing the capabilities of their equipment? The answer might not always be clear, but the journey towards improvement is vital in the glass fabrication industry.

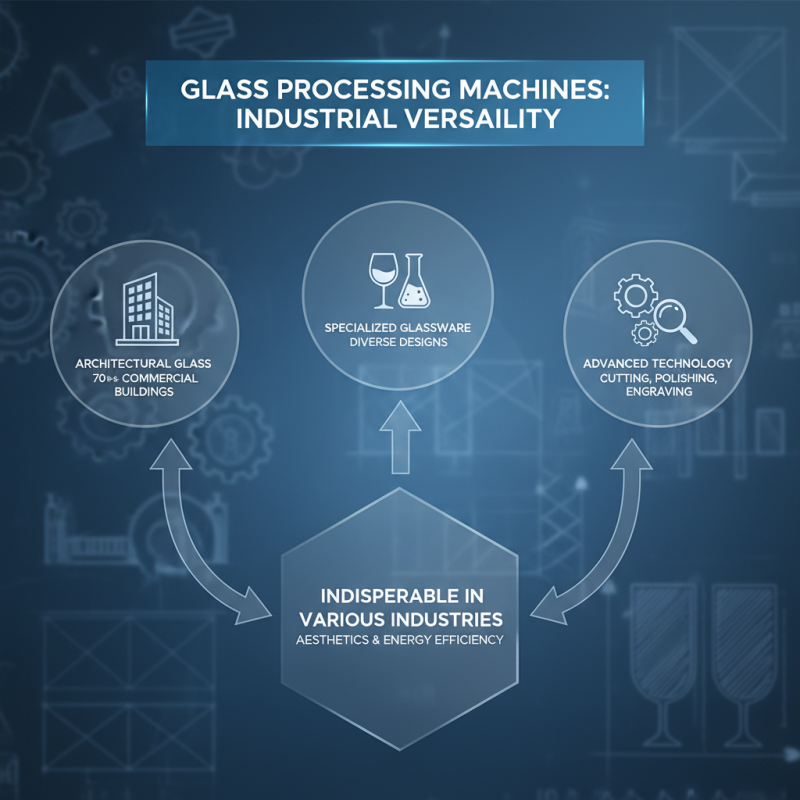

Versatility of Glass Processing Machines for Diverse Applications and Designs

Glass processing machines have become indispensable in various industries due to their versatility. They can handle a range of applications, from architectural glass to specialized glassware. In the construction sector, reports show that over 70% of commercial buildings now feature glass facades, enhancing aesthetics and energy efficiency. With advanced cutting, polishing, and engraving technologies, these machines meet diverse design requirements.

This adaptability is crucial as designers seek innovative solutions. Glass processing machines allow for customized shapes and finishes, meeting the rising demand for unique design. According to recent industry data, nearly 35% of architects prioritize custom glass installations in their projects. However, not all glass processing machines deliver the same quality. Variability exists in precision and durability, hinting at the need for careful selection.

Moreover, while these machines boost productivity, they can also have steep learning curves. Operators may find challenges in mastering complex software or machinery settings. Professionals must invest time in training to ensure optimal use. Despite these hurdles, the benefits of using glass processing machines far outweigh the drawbacks. The industry's growth shows a promising future with more innovations on the horizon.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us