Top 10 Benefits of Using CNC Glass Cutting Machines for Your Business

In today’s competitive market, the integration of advanced technology in manufacturing processes is essential for staying ahead. The CNC glass cutting machine has emerged as a pivotal tool for businesses looking to enhance efficiency and precision in their glass processing operations. According to a report by MarketsandMarkets, the global glass processing market is projected to reach $180 billion by 2025, highlighting the growing demand for high-quality glass products that can be achieved through CNC machinery.

Experts in the field, such as Dr. Jonathan Lee, a renowned mechanical engineering specialist, have emphasized the transformative impact of CNC technology, stating, "CNC glass cutting machines not only increase production speed but also significantly reduce waste and rework, offering manufacturers a remarkable return on investment." As businesses strive to optimize their operations, understanding the top benefits of CNC glass cutting machines is crucial for leveraging these advancements to drive growth, improve quality, and enhance customer satisfaction. This article delves into the top 10 advantages of utilizing CNC glass cutting machines for your business, showcasing how this technology can revolutionize glass processing.

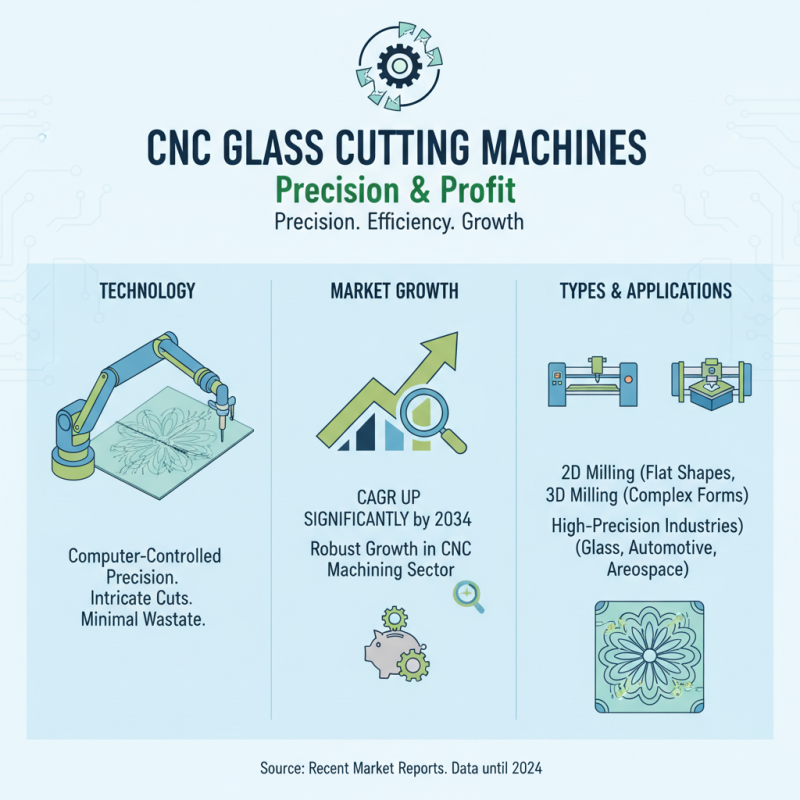

Overview of CNC Glass Cutting Machines

CNC glass cutting machines have revolutionized the way businesses handle glass fabrication, bringing precision and efficiency to the forefront. These machines utilize advanced computer-controlled technology to achieve intricate cuts with minimal wastage. According to recent market reports, the CNC machining sector is witnessing robust growth, with a compound annual growth rate (CAGR) projected to enhance significantly by 2034. The differentiation in types, such as CNC 2D and 3D milling machines, allows businesses to select the suitable technology that aligns with their specific needs, especially in high-precision industries like glass fabrication.

Implementing CNC glass cutting machines can streamline production times and ensure quality consistency. This technology enables operators to create complex designs that were previously considered impractical with traditional methods. For businesses looking to scale, integrating CNC technology is not just a trend; it’s a strategic imperative to stay competitive in an evolving market.

**Tip:** When selecting a CNC glass cutting machine, consider focusing on models that offer easy integration with existing workflows to maximize productivity. Additionally, ensure you examine specifications related to precision and the types of materials they can handle to better serve your target market.

Enhanced Precision and Accuracy in Glass Cutting

The precision and accuracy provided by CNC glass cutting machines are paramount for businesses aiming to enhance their operational efficiency. As the industry evolves, the global market for precision industrial knives is projected to grow from $244.9 million in 2024 to $333.1 million by 2032, with a compound annual growth rate (CAGR) of 4%. This growth highlights the increasing demand for advanced cutting technologies that can ensure more precise and consistent outcomes in manufacturing processes.

CNC glass cutting machines utilize sophisticated algorithms and computer-controlled systems to achieve remarkably high levels of precision. This technology reduces human error, resulting in cleaner cuts and minimizing material wastage, which is essential for maintaining cost-effectiveness. Moreover, the implementation of AI in supply chain management—such as optimizing inventory and reducing waste—further complements the capabilities of CNC machinery. As seen in various industries, integrating AI solutions can lead to improved accuracy in forecasting needs and identifying growth opportunities while enhancing the overall efficiency of production lines, thus making CNC glass cutting an indispensable addition for businesses striving for excellence in glass manufacturing.

Top 10 Benefits of Using CNC Glass Cutting Machines for Your Business - Enhanced Precision and Accuracy in Glass Cutting

| Benefit |

Description |

Impact on Business |

| Enhanced Precision |

CNC machines provide high accuracy in cut dimensions, reducing wastage. |

Improved product quality and reduced material costs. |

| Increased Efficiency |

Automated cutting reduces manual labor and speeds up the production process. |

Higher output and ability to meet larger orders. |

| Versatility |

CNC machines can cut various shapes and sizes, accommodating different designs. |

Ability to cater to diverse customer needs. |

| Reduced Waste |

CNC cutting optimizes material usage, lowering waste levels. |

Cost-effective production and eco-friendly practices. |

| Safety |

Automated CNC cutting reduces the risk of accidents associated with manual cutting. |

Safer work environment for employees. |

| Consistency |

Every cut is identical, ensuring uniformity in production. |

Stronger brand reputation due to consistent product quality. |

| Lower Labor Costs |

Less manual intervention required, leading to reduced labor expenses. |

Increased profitability. |

| Design Flexibility |

Easily programmable to adapt to new designs and modifications. |

Ability to innovate and respond to market trends quickly. |

| Long-term Cost Savings |

Initial investment offsets through decreased waste and labor costs. |

Improved financial sustainability. |

| Career Development |

Employees can develop technical skills related to CNC technology. |

Enhanced workforce capabilities and job satisfaction. |

Increased Production Efficiency and Speed

CNC glass cutting machines play a pivotal role in enhancing production efficiency and speed for various industries. According to a recent report by Grand View Research, the global CNC glass cutting machine market is projected to reach $4.8 billion by 2025, fueled by the increasing demand for precision glass cutting in construction and automotive sectors. These machines not only optimize workspace by minimizing material waste but also accelerate the cutting process, with speeds up to 20 times faster than traditional manual methods.

To maximize the benefits of CNC technology, it's essential to implement best practices in your operations. One effective tip is to invest in software that allows for optimized cutting patterns based on your specific glass types and thicknesses. This not only saves time but also reduces the frequency of job restarts. Another valuable tip is to schedule regular maintenance checks, ensuring your machines remain in peak condition, thus avoiding unexpected downtime that can hinder productivity.

Utilizing CNC glass cutting machines enables businesses to respond more quickly to customer demands, which is critical in today's fast-paced market. The ability to deliver high-quality products faster gives companies a competitive edge, allowing them to fulfill larger orders and gain client trust. Data from Allied Market Research indicates that companies that adopt advanced CNC technologies can improve their turnaround time by 30%, a game changer in high-stakes projects.

Cost-Effectiveness and Waste Reduction Benefits

The adoption of CNC glass cutting machines offers significant cost-effectiveness and waste reduction benefits that can greatly enhance operational efficiency for businesses in the glass industry. According to a report by IBISWorld, companies that invest in CNC technology have reported reductions in material waste by up to 30%, as these machines utilize advanced software to optimize cutting patterns. This reduces both the raw material costs and the need for additional inventory, allowing businesses to allocate resources more effectively.

Moreover, CNC glass cutting machines often require fewer manual interventions, which translates into lower labor costs. A study from Technavio indicated that automation in manufacturing, including glass cutting, can decrease labor costs by approximately 20-25%. This shift not only improves productivity but also minimizes the risk of human error, resulting in higher-quality outputs and further eliminating waste. By streamlining operations in this way, businesses can not only achieve significant savings but also improve their bottom line through enhanced operational sustainability practices.

Versatility in Design and Material Compatibility

CNC glass cutting machines offer remarkable versatility in design and material compatibility, making them integral to modern glass fabrication businesses. According to a report from MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, highlighting the increasing reliance on automated solutions in various industries, including glass manufacturing. These machines can handle a wide variety of glass types, including tempered, laminated, and decorative glass, allowing businesses to cater to diverse customer needs without compromising on precision or quality.

Moreover, the adaptability of CNC glass cutting machines extends to intricate design capabilities. A study from Technavio indicates that the demand for customized glass products has surged by approximately 17% annually, driven largely by advancements in CNC technology. This allows operators to execute complex shapes and patterns effortlessly, from detailed etchings to structured cutouts. The ability to produce unique glass designs not only enhances product offerings but also positions businesses to compete more effectively in a crowded market, ultimately leading to increased customer satisfaction and loyalty.

Top 10 Benefits of Using CNC Glass Cutting Machines for Your Business

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us