Unlocking the Advantages of Glass Edging Processing Machinery for Global Buyers

In recent years, the demand for precision and quality in glass processing has surged, placing a spotlight on the pivotal role of the Glass Edging Processing Machine in the industry. According to a report by Grand View Research, the global glass processing market is expected to reach USD 51.5 billion by 2025, with a compound annual growth rate (CAGR) of 4.3% from 2019 to 2025. This growth is driven by the expanding applications of glass in construction, automotive, and interior design sectors. As manufacturers and global buyers seek innovative solutions to enhance their production efficiency and output quality, investing in advanced glass edging technologies becomes imperative. By leveraging these sophisticated machines, businesses can unlock numerous advantages, including improved edge precision, reduced waste, and faster turnaround times, thus boosting their competitive edge in the bustling international market.

Understanding Glass Edging Processing: Key Features and Functions

Glass edging processing machinery has become an essential asset for manufacturers looking to produce high-quality glass products. Understanding the key features and functions of this technology can significantly enhance the production process. One of the main features is the precision offered by modern glass edging machines. These machines employ advanced algorithms and tools to achieve consistent edge profiles, which is crucial for aesthetic and functional purposes in various applications, from architectural glass to automotive windows.

Another significant function of glass edging processing machinery is its versatility. These machines are designed to handle a wide range of glass thicknesses and types, allowing manufacturers to cater to diverse market demands. The ability to quickly switch between different edging styles—such as flat, bevel, or round edges—enables businesses to adapt to customer preferences efficiently. Moreover, the automation capabilities integrated into modern machinery reduce labor costs and enhance productivity, providing a competitive edge in the global market.

Embracing these advantages not only streamlines the manufacturing process but also elevates the overall quality of glass products, making it an invaluable investment for buyers worldwide.

Advantages of Automated Glass Edging Machinery for Mass Production

Automated glass edging machinery has revolutionized the glass manufacturing industry, offering significant advantages for mass production. According to a report by Mordor Intelligence, the global glass processing equipment market is projected to grow at a CAGR of 4.7% from 2021 to 2026. This growth is largely driven by increased demand for precision and efficiency in glass fabrication, and automated edging machines play a pivotal role in meeting these needs. By utilizing advanced robotics and computer numerically controlled (CNC) systems, manufacturers can achieve greater accuracy in glass edge finishes, reducing the error margin to as low as 0.5 mm, a critical factor for high-quality glass products.

Furthermore, automated glass edging machines enhance production speed, allowing factories to significantly increase their output without compromising quality. The same Mordor Intelligence report highlights that businesses implementing automation report a productivity increase of up to 30%, which can result in substantial cost savings and improved profit margins. The ability to produce intricate designs and shapes at scale not only meets consumer demands for customization but also enhances competitiveness in a rapidly evolving market. As global buyers seek efficiency and precision, investing in automated glass edging machinery emerges as a strategic advantage in the manufacturing landscape.

Unlocking the Advantages of Glass Edging Processing Machinery for Global Buyers

| Feature |

Advantage |

Impact on Production |

Cost Efficiency |

| Automated Processing |

Increased precision and consistency |

Reduces error rates, leading to higher quality |

Lower labor costs |

| High-Speed Operations |

Faster turnaround times |

Increases output efficiency |

Maximizes production volume |

| Versatile Design |

Ability to handle various glass types |

Flexibility in product offerings |

Reduces need for multiple machines |

| User-Friendly Interface |

Simplified operation and monitoring |

Decreases training time for operators |

Improves overall workflow efficiency |

| Energy Efficiency |

Reduces operational energy consumption |

Lower overall production costs |

Promotes sustainable practices |

Essential Considerations for Choosing the Right Glass Edging Equipment

When selecting the right glass edging processing machinery, buyers must consider several essential factors that can significantly impact their operations. According to a report by the Glass Association, the global glass processing equipment market is projected to reach $7.4 billion by 2025, indicating a robust demand for advanced machinery. Key considerations include the machine’s precision, speed, and versatility in handling various glass types. For instance, high-precision glass edging machines can achieve tolerances within ±0.1 mm, which is crucial for applications in architecture and automotive industries where safety and aesthetics are paramount.

Another critical aspect is the integration of technology such as automation and energy efficiency. A study from the International Glass Industry highlights that automated glass edging systems can increase productivity by up to 30%, while also reducing labor costs and minimizing waste. Additionally, buyers should evaluate the after-sales support and the availability of spare parts, as these factors can influence the long-term operational efficiency of the machinery. By carefully assessing these considerations, global buyers can make informed decisions that enhance their competitive edge in the evolving glass processing market.

Maintaining Glass Edging Machines for Optimal Performance

Maintaining glass edging machines is crucial for ensuring optimal performance and longevity in production processes. According to industry reports, proper maintenance can increase the lifespan of these machines by up to 30%, resulting in significant cost savings for manufacturers. Regular maintenance tasks should include cleaning, lubrication, and inspection of wear parts to prevent unexpected breakdowns. Keeping detailed maintenance records also helps operators track performance trends and anticipate possible issues before they escalate.

Tips for Maintenance: Regularly check for any misalignment in the edging tools, as misalignment can lead to uneven edges and increased wear. Additionally, ensure the cooling system is functioning correctly; overheating can cause permanent damage to critical components of the machine. Operators should also be trained in troubleshooting basic issues to minimize downtime.

Investing in a robust maintenance schedule not only enhances machine efficiency but also contributes to product quality. Research shows that companies that adhere to strict maintenance routines can see a 20% improvement in output quality, making it a worthwhile endeavor for global buyers looking to optimize their glass edging operations.

Comparative Analysis: Glass Edging Techniques from Around the World

As the glass processing industry continues to evolve, various glass edging techniques from around the world are gaining prominence. A recent report by the Glass Machinery Industry Association highlights that global demand for advanced glass processing machinery has increased by 15% in the past three years. This surge is driven by the need for precision and efficiency in glass edging, which is crucial for manufacturers looking to enhance product quality and reduce waste.

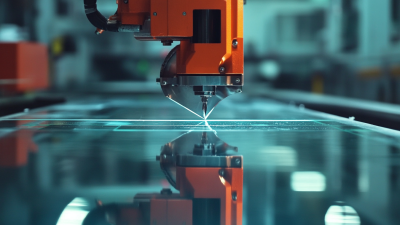

In regions such as Europe and North America, waterjet edging technology has become a preferred method due to its ability to cut intricate designs with minimal material loss. In contrast, Asian markets tend to favor CNC (Computer Numerical Control) machines for their capability to automate the edging process, leading to enhanced production speeds. The International Glass Association's studies indicate that CNC technology adoption in Asian countries increased by 20% in 2022, underscoring a significant shift in manufacturing paradigms. By leveraging these distinct edging techniques, global buyers can unlock numerous advantages, from cost savings to superior finish quality, ultimately leading to heightened competitiveness in the global market.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us