2026 Top Glass Edging Processing Machine Innovations?

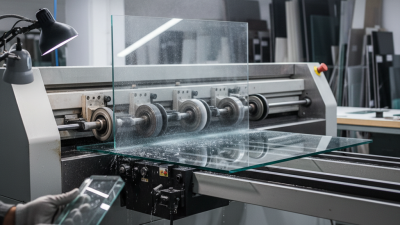

In 2026, the landscape of glass edging technology continues to evolve rapidly. Glass Edging Processing Machines play a crucial role in this transformation. These machines shape and refine glass edges, ensuring a polished finish.

Manufacturers are focusing on innovation, integrating advanced features. Automated processes increase efficiency and reduce labor costs. Moreover, precision tools enhance the quality of the edge, minimizing imperfections. However, some users find these advancements challenging. Training staff to handle complex machinery requires time and effort.

The demand for customization is rising. Clients seek designs that are unique and intricate. This adds pressure on manufacturers to adapt. They must balance speed and quality. Such challenges could lead to gaps in the production process. It’s clear that the evolution of Glass Edging Processing Machines is not without its hurdles. Embracing these innovations needs careful consideration and reflection.

2026 Innovations in Glass Edging Technology: An Overview

In 2026, glass edging technology is set to undergo significant advancements. Innovative features are appearing in new machines that redefine efficiency and precision. The latest models focus on automation, enabling seamless operations. Operators can input specifications easily. This reduces human error and enhances production speed.

New materials are making machines lighter yet more durable. Improved blades and tools offer smoother finishes. These innovations can lead to faster turnaround times. However, challenges remain in adapting to these technologies. Training workers effectively is crucial. Companies may struggle to keep pace with rapid changes. As glass edges become cleaner and sharper, the demand for skilled operators rises.

Some machines may not live up to expectations. Performance under high capacities can be inconsistent. Companies should consider reliability when investing. Regular maintenance is essential. Without it, even the best technology can falter. It’s a constant balancing act between innovation and practical application. As the industry grows, so does the need for adaptability and foresight.

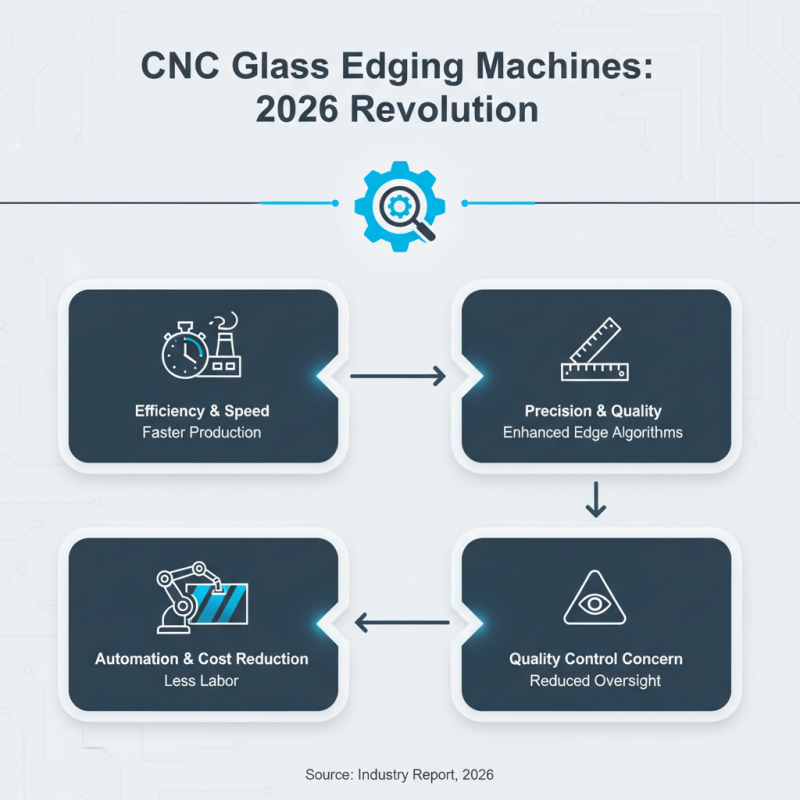

Key Advancements in CNC Glass Edging Machines for 2026

In 2026, CNC glass edging machines are set to revolutionize the industry. Key advancements focus on efficiency and accuracy. New algorithms will enhance edge quality. These innovations enable faster production without compromising precision. Manufacturers prioritize automation, reducing labor costs. Higher automation often leads to less oversight, which can be a concern for quality control.

Tips: Regularly monitor machine outputs. Adjust settings based on quality checks. Over-reliance on automation may result in overlooked defects.

Advancements in user interfaces are significant. Touchscreen controls allow for easier operation and monitoring. Operators can quickly adjust settings on the fly. However, with technology improving, some operators may resist adapting to new systems. Training becomes essential here.

Another focus is energy efficiency. Modern machines are designed to consume less power. This can cut costs over time. Nonetheless, companies must assess the trade-off between initial investments and long-term savings. Implementing new machines can be a challenge. Inadequate preparation can lead to downtime or inefficiencies.

Impact of Automation on Glass Edging Efficiency and Precision

Automation is reshaping the glass edging industry. Recent studies show that automated machines increase efficiency by up to 30%. They also enhance precision, reducing errors in cutting and finishing. The demand for high-quality glass products drives this innovation.

However, the initial investment in automation technologies can be daunting for smaller manufacturers.

Incorporating automation often requires significant changes in existing workflows. Many companies struggle to adapt. Training staff for new technologies is another challenge. Yet, those that embrace these innovations see longer-term benefits. Reports indicate that 75% of companies that upgraded to automated systems experienced a notable reduction in waste.

Moreover, the impact on labor is complex. While automation reduces manual tasks, it also creates new job roles. Technicians and engineers are needed to oversee automated processes. The shift raises questions about workforce balance. Finding the right blend of human expertise and machine efficiency is crucial for sustained success in glass edging.

Emerging Materials in Glass Edging Equipment for Sustainability

The glass edging industry is embracing emerging materials that prioritize sustainability. Recent studies show that eco-friendly alternatives can significantly reduce environmental impact. For instance, using recycled glass in production not only lessens waste but also decreases energy consumption. Reports indicate that incorporating recycled content can lower CO2 emissions by up to 30%.

Innovations in this space highlight the use of advanced materials like bio-based epoxy resins. These materials offer comparable strength to traditional options but are less harmful to the planet. Despite these benefits, challenges remain. The production process for these sustainable materials can be more complex and costly. Companies often hesitate to invest due to these initial hurdles.

Furthermore, new adhesives and coatings are being developed to enhance the durability of glass products. While these advancements can improve performance, they may not be as widely adopted yet. Industry experts argue that more extensive testing is required to ensure reliability. Overall, the push for sustainable materials in glass edging is crucial, but the path forward requires careful consideration and continuous innovation.

2026 Innovations in Glass Edging Processing Machines

Market Trends: Growth Projections in Glass Edging Processing Machinery

As the industry evolves, glass edging processing machinery is witnessing substantial growth. The global market is expected to reach $2.7 billion by 2026, according to a recent report. This growth is driven by rising demand in construction and automotive sectors. Companies are investing heavily in advanced technologies to enhance production efficiency.

The introduction of automated processes is a game changer. It allows for precise cutting and shaping, reducing waste. Many manufacturers are integrating AI for better quality control. Data suggests that automation can reduce operational costs by up to 30%. However, the transition poses challenges. Not all companies have the resources to upgrade.

Sustainability is also a pressing issue. The demand for eco-friendly materials is increasing. It's vital for companies to adapt to these trends. Yet, some may struggle with the costs of sustainable practices. Balancing innovation and environmental responsibility remains a key hurdle for the industry.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us